Non-woven-materials cutting is a fundamental task for Tier 1 & 2 suppliers making automotive soft-trim products. Automating that process can be the key to increasing throughput, lowering costs, and solving the current difficulties in finding employees.

Automotive OEMs primarily focus on three key characteristics in their Tier 1 & Tier 2 suppliers:

- Quality

- Delivery

- Cost

Delivering on all three of these traits is clearly not easy. But one of the ways automotive soft-trim suppliers are succeeding in meeting your expectations is increased reliance on automated robotic-cutting technologies.

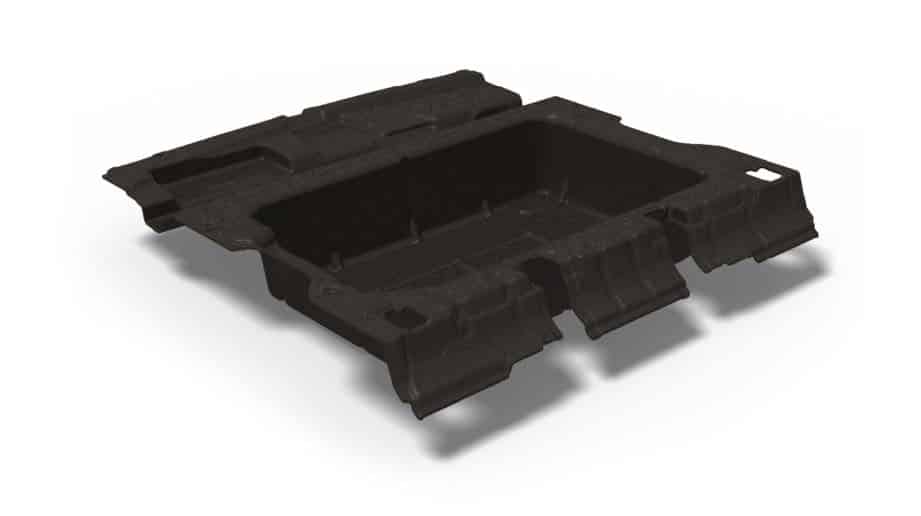

A key step in producing soft trim is cutting non-woven materials. Soft-trim component suppliers rely on one or more of several cutting technologies, including waterjet, laser, router, and hand-cutting. Waterjet is typically the most cost-effective solution, and integrating automation systems into production lines greatly multiplies the benefits.

Waterjet cutting and trimming

“The days of using presses with large, costly, and potentially dangerous metal dies to cut non-woven materials are numbered,” says Scott Light, Regional Sales Manager at Shape Process Automation (SPA). “While they provide great throughput, dies are complex and expensive to create; and they are difficult, if not impossible, to modify. A product specification change typically means a new die, with high costs and long lead time and downtime.”

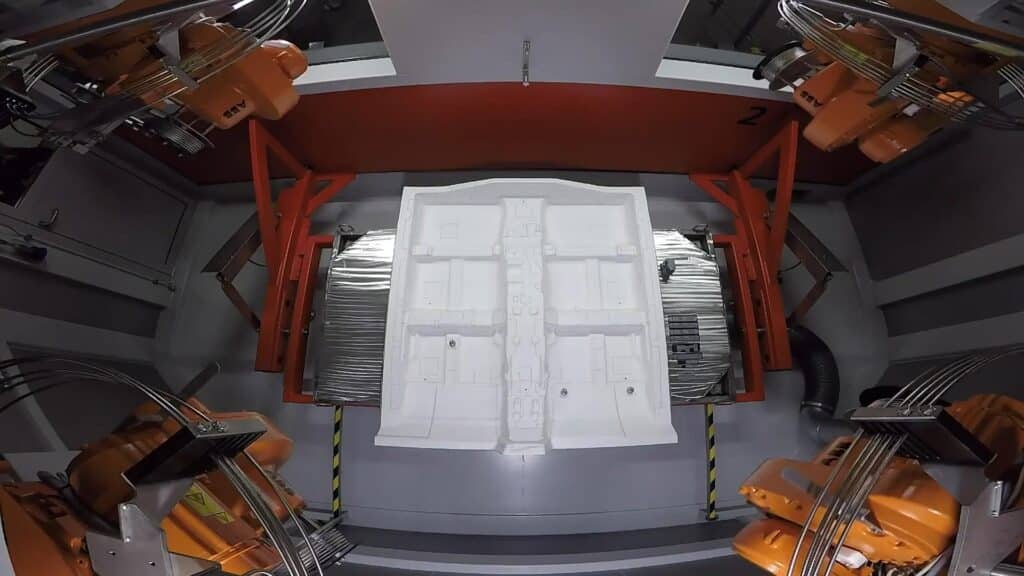

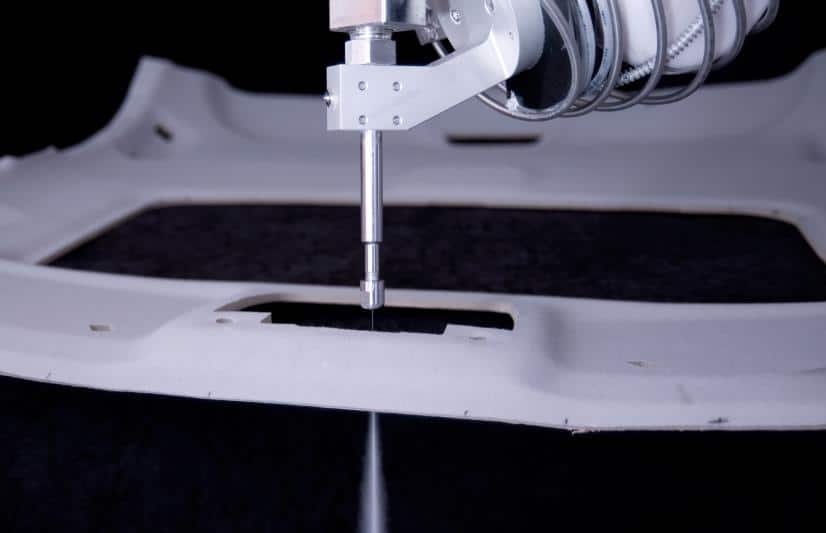

Waterjet cutting, on the other hand, eliminates the negative aspects of metal dies, replacing them with cutting heads mounted on robotic arms. Instead of creating a new die to incorporate product changes, all that’s required is re-programming the robot to a new tool path.

The fact that the cutting pattern and process parameters are programmable makes it simple and affordable to instantly make changes. Whether it’s making small adjustments to a program, adding or modifying features, or “retooling” for a new part, the only cost is the time it takes for the operator to update the program.

Cutting speed is obviously faster than can be achieved by any manual process. The ability to use multiple robots, each with their own cutting head, greatly increases throughput over most other automated and restrictive cutting technologies. And those 3D cutting heads can operate omni-directionally in any direction, further increasing throughput.

Automating your cutting processes

Process automation using robots provides several proven benefits, in addition to greater productivity:

- Enhanced quality

- High repeatability

- Increased operator safety

Today’s employment environment brings another important benefit to the forefront. Businesses of all types are struggling to find and retain enough qualified employees. That problem is particularly acute regarding unglamorous and physically challenging manufacturing jobs like manually loading and unloading production machines. Automation reduces the number of these unsatisfying, repetitive tasks and allows your operators to step up to higher-level, higher-value roles that encourage them to stay with your organization.

Tier suppliers sometimes shy away from “expensive” automated solutions due to concerns about sufficient return on their investment. Those concerns are typically inaccurate and unwarranted considering the flexibility and longevity of automated systems.

The ROI on even a large, multi-year production contract may not clearly justify an investment in automation. But the payback picture changes when you consider that these systems can be readily reconfigured to new parts or entirely new platforms. Robotic-automation systems are seldom, if ever, obsoleted due to changes in production requirements; the systems are simply modified or repurposed.

“Some potential automation-system buyers worry about the longevity of their system,” says Duane Snider, Regional Sales Manager at SPA. “They wonder how many years their investment will continue to pay off, but they don’t need to be concerned. There are many, many, many installations out there still in production after 80,000+ hours of operation … nearly two decades … when the systems are properly maintained. I know of one robot that’s still plugging away after 110,000 hours. The payback on automation is practically guaranteed.”

The reality is this: the hourly operating costs for a high-output, multi-head robotic cutting system are significantly lower than the wages for an entry-level operator. These workcells reliably operate 24/7, offering substantial benefits to your bottom line.

Making a smart automation decision

Automotive tier suppliers considering how best to automate their processes need to ensure that they invest in the right cutting technology and automation design. As you investigate potential integrators, be certain they are dedicated and experienced in delivering the best solution to meet your needs.

Waterjet is usually the right solution for soft trim, but rather than telling potential automation suppliers that you need a certain cutting technology, share your production specifications and goals with them. Then let your integrator determine what the appropriate, most cost-effective technology is and how to best integrate it in your processes.

“Shape Process Automation is an advanced material processing solutions company that offers a range of cutting technology,” says Snider. “Our base robots incorporate a highly refined, process-specific suite of control software features that ensure high accuracy, high-speed tool path control. SPA’s user-friendly JetWare easily adapts to various geometries and provides easy-to-use, automatic TCP nozzle calibration for maximum uptime. Based on our broad expertise in automated cutting solutions, we will recommend the best solution to meet each customer’s unique requirements.” You want the production technology that will help you make more parts at a competitive cost that will bring in additional business. Automating your non-woven-materials cutting processes is likely to be a sure-fire way to help you achieve that goal.

Recent Comments