Removing coatings from parts is a basic aircraft MRO activity. One coating-removal process has clear benefits over the other methods available.

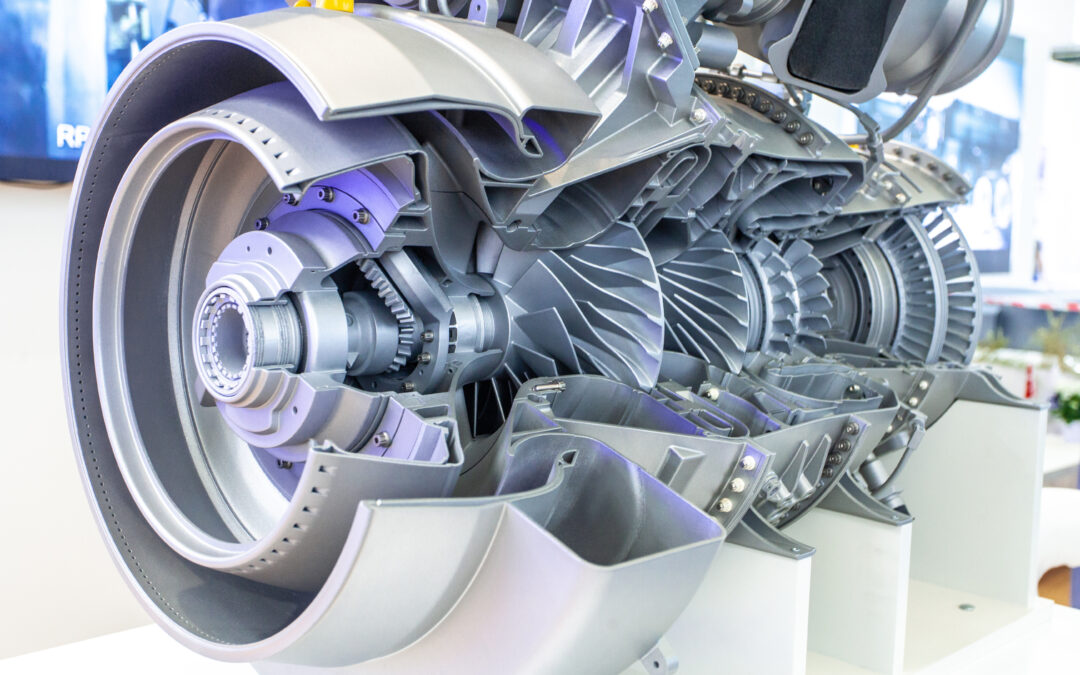

Modern commercial aircraft engines are genuine wonders of engineering. They are both incredibly reliable and durable, with engine-related accidents statistically very rare. That’s especially impressive considering the harsh environmental conditions and near constant operation, with typical time between overhauls of 10,000 to 20,000 flight cycles.

During those overhauls, one critical maintenance, repair, and overhaul (MRO) activity is removing and reapplying the thermal spray coatings (e.g. abradable, thermal barrier, wear protection) used to protect critical, high-wear components like turbine and compressor blades, burner cans, combustors, knife-edge seals, etc. There are many technologies available to remove these coatings, each with a unique set of benefits and drawbacks.

Stripping technologies

Refurbishing aerospace engine components, both commercial and military, has a simple but challenging goal; remove the old coatings without damaging or removing the component base material. Certain technologies provide clear advantages in achieving that goal.

Commonly used technologies include:

Mechanical Removal: Grit/sand blasting, machining, and grinding are legacy technologies that are well known and technically simple, but can damage delicate surfaces and are typically labor-intensive.

Chemical Removal: Relies on various chemical solutions (e.g. sulfuric acid, nitric acid), to dissolve or soften the coatings with no damage to the base material.

Ultra High-Pressure Waterjet Stripping (WJS): Implemented via automated robotic solutions, waterjet(s) induces a shearing force onto the coating that can remove all types of coatings.

Waterjet Stripping vs Chemical Removal Processes

These two technologies are well-known and proven but when considering which approach is the best fit for your operations, MRO facilities should consider these below factors.

| Waterjet Stripping | Chemical Removal Process | |

|---|---|---|

| Efficiency | Fast removal of coatings. Typically, 3-5 hours for a combustor liner. | Requires long dipping time, sometimes with rinse and sandblasting. Typically, 24-48h for a combustor liner. |

| Part Complexity | Unable to access some areas of complex parts. | Ability to remove coatings from parts of any complexity. |

| Safety | Virtually no safety concerns. | Less dangerous than mechanical processes, but can expose technicians to harmful chemicals. |

| Environmental | No environmental impact due, water is recycled. | Many chemicals contain hazardous materials that require proper handling and disposal that is regulated and controlled. |

| Applicability | Few restrictions on applicable components or coatings, which enables greater flexibility in production planning. | To efficiently remove and avoid component damage and unwanted residues, chemicals must be matched to specific coatings. |

| Control | Totally controllable process, with the ability to adjust jet pressures on the fly for different areas of the component. | Less precise than mechanical methods, and larger coating areas can be not completely removed. |

| Cost | Lower operating, and minimal material and labor costs. | Higher operating, material, and labor costs. |

Selecting the Right Process

Automated waterjet stripping provides the most consistent and environmentally friendly solution, without the potential drawbacks of chemical stripping and other mechanical processes.

Working with an industry expert with extensive knowledge in high pressure technology, automation, and integration provides the opportunity to incorporate a turnkey system in your engine MRO facility. Qualification, part programming, and process training are just a few of the advantages that a key partner in this industry can offer.

The initial implementation costs are offset by higher throughput that results in shorter turnaround time (TAT) for aircraft engines and elimination of hazardous-waste handling.

Automation integrators can provide an analysis based on your project specifications and work with you on a solution that is aligned with your MRO operational goals.

Recent Comments