Robotic Waterjet Cutting

Cut virtually any material, any shape with waterjet. Fast. Repeatable. Precise. GET A TEST CUTAmp Up Factory Production with Waterjet

Robotic waterjet cutting solutions combine the versatility of waterjet with the smart manufacturing power of automation, increasing manufacturing flexibility, capacity, and output.

Highly recognized as the most versatile material processing solution, waterjet cuts virtually any material, any shape – with ease. From 2-dimensional flat stock to 3-dimensional molded components, metals to fabric, plastic composites, and food, waterjet is an effective, efficient cutting solution.

Wondering if waterjet is the right fit for you? We’re here to help.

Highly Reliable and Path Accurate

Cold Cutting Process (no HAZ)

Hard, Soft or Multi-Layer Materials

Minimal Fixturing

Flexibility to Program Infinite Parts

Increase Throughput with Multiple Robots

Custom Waterjet Cutting Solutions – Designed for You.

Every 6-Axis robotic waterjet cutting cell is designed and configured to meet your specific manufacturing needs – from a single robot to multiple robot cells, complete with product fixturing, and material handling. Our experts are with you, end-to-end, as you work to improve your production.

- Composite structures

- Automotive carpets

- Trimming of automotive headliners

- Automotive door panels

- Fiberglass heavy truck exterior components

- Glass food jars (food industry)

- Rubber shoes soles (general industry)

- Boats, recreational vehicles

- Hot tubs

- And more…

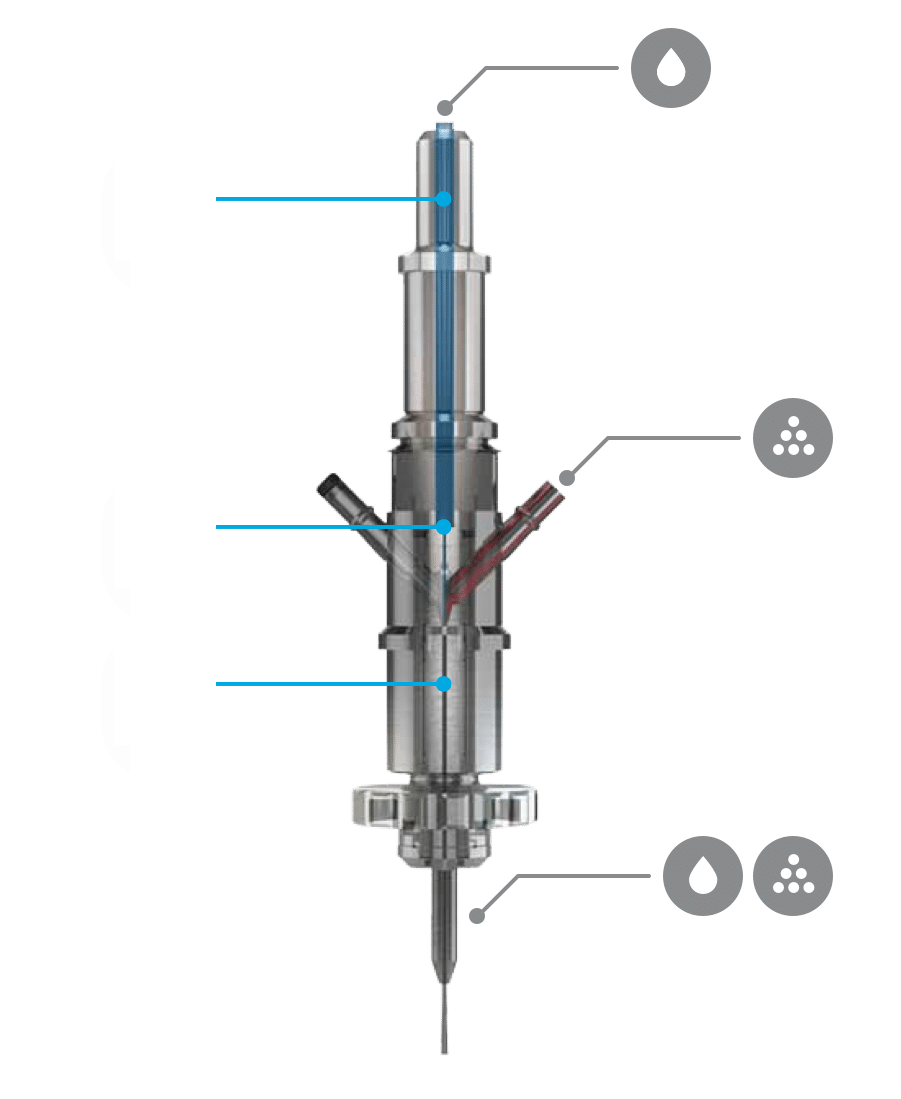

Generate Pressure

Content Here

Convert Pressure to Velocity

Content Here

Introduce Garnet

Content Here

How Waterjet Cutting Works: A Natural Solution for Excellence

Waterjet cutting technology involves the ultrahigh pressurizing (30,000 to 87,000 psi) of filtered tap water, which is then passed through a small diameter orifice of .007 to .014” diameter.

Traveling at a high speeds of up to 900 m/sec, with sufficient kinetic energy to cut an astonishing array of materials, waterjets are unmatched in versatility. A cold cutting process, waterjet won’t change the properties of the material you’re cutting (as with other processes like laser or flame cutting), and it cuts without the use or creation of noxious gases, liquids, or hazardous by-products.

Pure waterjet consists of high-pressure water only. For cutting hard materials like metals, composites, glass, and stone, abrasive is added into the waterjet cutting stream.

Waterjet Cutting ROI Calculator

Sapphire Vs. Diamond Orifices

Carbon Fiber Cutting and Trimming using advanced 3D Robotics with Abrasive Waterjet Process

The flexibility of Shape Process Automation’s robotic waterjet systems enables manufacturers to make the most of their capital investment. Trimming programs can easily be changed or added so that several parts can be cut on the same system with virtually no set-up time. All of our trimming solutions are safe, cost-effective and highly productive.

Waterjet Cutting Systems

Depending on your production demands, each of these cells can be supplied with single, dual, triple or quad robot configurations, and if your demands are greater overhead gantries can be configured with up to six robots, paired with a complete UHP plumbing package – from pump to nozzle – sized to meet your production’s cutting requirements.

FLOOR MOUNT PEDESTAL

FIXTURE: Varies

ROBOT: Fanuc M20iA/20

PUMP: H20,Flow or KMT

OVERHEAD GANTRY

The 4-post gantry is accessible from 1 of 2 sides, and can be combined with an upper mezzanine option so you can minimize your valuable footprint thereby maximizing the return on your investment. This configuration can accommodate between 1 and 6 robots overhead.

When combined with a vacuum cyclone unit for part fixture clamping, manual load and unload is exceptionally quick and clean for your operators.

FIXTURE: 72” X 140”

ROBOT: Fanuc M20iA/20

PUMP: H20,Flow or KMT

ROTATING WALL

The RW (rotating wall) solution offers single side access which allows waterjet trimming inside the cutting cell while the operator is able to unload and load part from the outside, This configuration can accommodate between 1 and 4 robots.

When combined with a vacuum cyclone unit for part fixture clamping, manual load and unload is exceptionally quick and clean for your operators.

FIXTURE: 36” X 60”

WALL MOUNT: Varies

ROBOT: Fanuc M20iA/20

PUMP: H20,Flow or KMT

Shape Process Automation AETool Solutions

iR Calibration Frame Shift formerly CellCal, is a calibration option that compensates for frame changes by establishing a MASTER frame that runs a frame search teach pendant program.

iR Calibration TCP option sets the Tool Center Point (TCP) automatically

iR Calibration TCP Shift option, formerly TCPCal, provides a cost effective, easy-to-use solution to recover the Tool Center Point (TCP) automatically.

Easy to Program Robotic Waterjet Software

Shape Process Automation solutions are designed to be easy to use, easy to recover, and easy to maintain. Complex cutting doesn’t mean complex programming.

Real Customer Experience

“As far as the cutout shape goes, the Offline Programming was dead on. These programs took one programmer about 8 hours to fine tune and it scrapped 5 parts. To create this program manually, it would take the programmer about 36-40 hours to write and fine tune into tolerance. Also, the manual way would probably scrap about 15-20 parts. In my opinion, the offline programs from Shape Process Automation was almost 100% accurate considering how much time it took to complete the program, how many parts were scrapped, and how far the TCP was from the target.”

– Jason Caroll, Robot Process Engineer at Johnson Controls

Industry Partners

Our systems and solutions combine deep application knowledge, world-class engineering standards, and quality fabrication. You expect the best, and so do we. Accordingly, we’re proud to partner with the following automation industry leaders.

Your Cut. Our Waterjet.

The Customer Solution Center (CSC)

Let us waterjet cut your parts in our Customer Solution Center. We can qualify cycle times, confirm cut quality, and even perform short production runs.