Turbine blades and other components of modern jet engines are coated to protect them from heat and wear. Newly developed coatings like cold HVOF are challenging engine refurbishment companies to find ways to remove these coatings.

Being on a commercial airliner is, statistically speaking, one of the safest places you can be. The odds of dying in a plane crash are about one in 11 million. Compare that to the very unlikely odds of being killed by lightning, which are about 1 in 15,000.

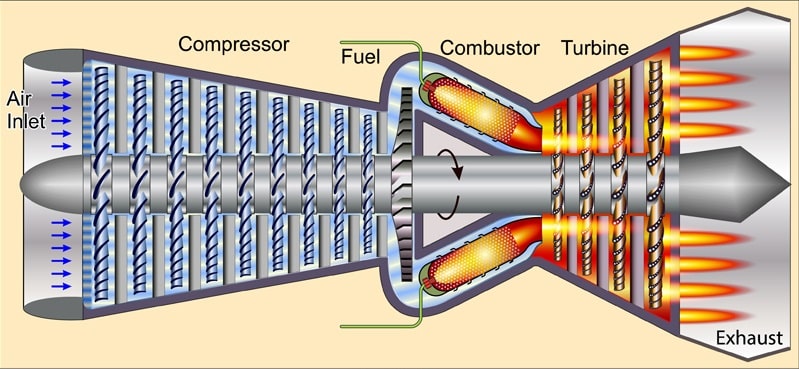

This exemplary equipment-safety record can be attributed to two primary factors. First, critical aerospace systems … propulsion, braking, control, etc. … have high levels of reliability and redundancy engineered in. Second, these aircraft systems receive extensively regulated maintenance. For jet engines, that maintenance includes inspection and refurbishment of the turbine blades and other combustion-chamber components that create the required thrust to propel aircraft through the skies.

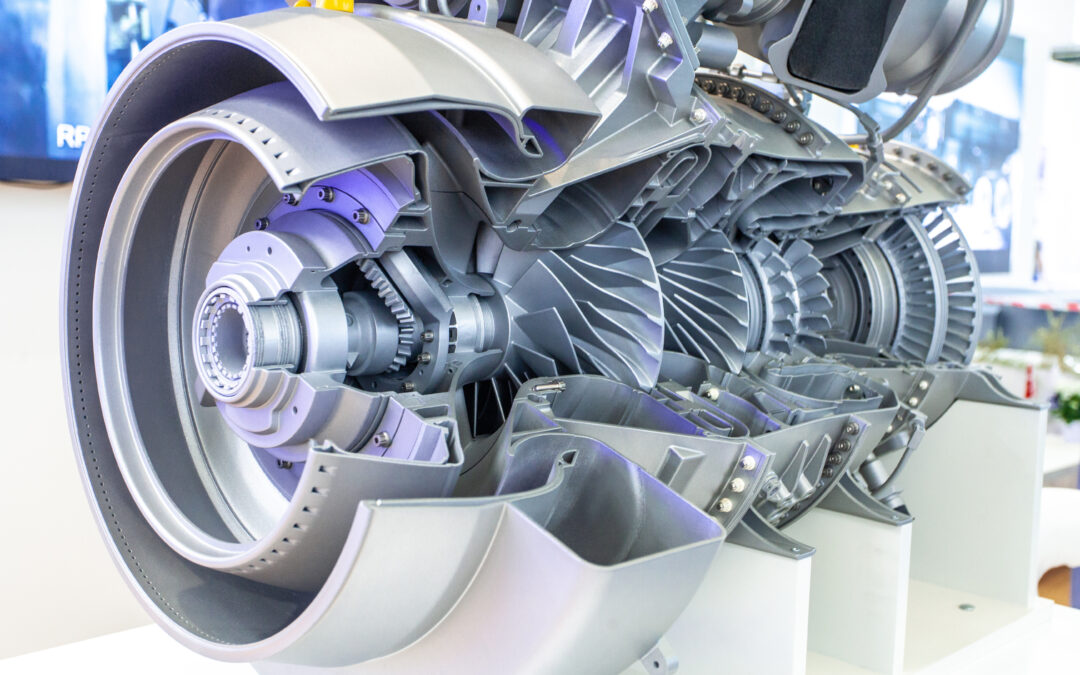

Compressor blades are made of high-strength titanium (first stages) and heat-resistant superalloys (last stages), typically coated with materials used to improve wear resistance.

Considering the rotational speed (as high as 25,000 RPM) for commercial jet engines, those coatings are obviously designed to stay in place. But during engine refurbishment, they must be removed to enable inspection, repair, and reapplication of fresh coatings.

Current coating technology

Combustor components are typically treated with a thermal barrier coating (TBC) made of ceramic materials with very low thermal conductivity. TBCs are most often applied using the electron beam physical vapor deposition process. The ceramic coatings have very poor heat conduction properties, helping to keep the components cooler.

Waterjet stripping (WJS) is commonly used to remove these coatings, typically in an automated process relying on industrial robots and automated process monitoring. WJS is a proven process that’s been shown to be highly reliable and path accurate, with the flexibility to adapt to the process to a virtually infinite range of part configurations.

Newer coating technologies are improving on the effectiveness of traditional approaches, but they are also creating problems for the shops that refurbish aircraft engine parts.

Cutting-edge coatings

The drive for increased reliability and efficiency of turbine engines has spawned several new coating technologies that are delivering significant benefits, extending blade life by up to 50% while improving engine efficiency by 2% or more.

New coating technologies include HVOF coating (high-velocity oxygen fuel), a hybrid coating process that employs a supersonic jet of gas to accelerate powder particles to high speeds, basically welding them to the substrate.

These coating technologies create a tighter coating-to-substrate bond than traditional technologies, extending coating life while improving the turbine blade’s resistance to corrosion and wear. But breaking those bonds during refurbishment can also mean removing some of the substrate.

It’s similar to removing well-bonded paint from a wall. Removal requires such aggressive processes that some of the wall be removed and sometimes damage, the wall. Removing strongly bonded coatings from turbine blades can be achieved using higher pressures, greater velocities, and/or more abrasive materials. But doing so means removing additional substrate, shortening the life and reducing the reliability of the blades.

Developing new coating-removal technologies

As with the older coating technologies, WJS is an effective method for completely removing both diffusion coatings. Achieving that goal with cold HVOF coatings, however, remains a challenge. Cold HVOF will likely become a much more widely used coating method in the near future.

And further out on the horizon, as hydrogen-fueled engines will come into use, even-more advanced coatings will be developed. The companies developing these coatings are concerned first and foremost with ensuring that the coatings stay on the component; there isn’t much thought to how they can be removed during engine refurbishment.

Fortunately, these components typically have a 10-year service cycle before they need to be inspected and refurbished. That gives companies like Shape Process Automation, a global industrial automation solutions provider, a window of opportunity to catch up with the required removal technologies. Of course, that window must include time not just to develop the technology, but to have it vetted and approved by the industry and government bodies that administer aerospace regulations.

The widely used and proven waterjet stripping process isn’t up to the task. Better results have been achieved by adding abrasives to the waterjet, but engine-component manufacturers have restricted the materials that can be used. Another approach is hyperjet technology, which increases the pressure to 90,000 psi. However, current repair manuals restrict maximum pressure to 60,000 psi. Shape is working with these manufacturers to identify appropriate abrasives/additions as well as potential changes to other process parameters.

Preparing for the future

With the average cost of a commercial jet plane ranging from approximately $100 to $400 million, the airlines want to get as much life, with as little maintenance, as possible to recover those costs. Shape Process Automation has trials underway of methods for HVOF coating removal. The results thus far are good, but are not yet a complete success.

Achieving success will require developing solutions that are not only effective from a technical standpoint, but also meet the stringent requirements of the engine manufacturer, aircraft owners, and various regulatory organizations. Given Shape’s success with creating viable solutions to other difficult process automation challenges, it’s highly probable they can develop a reliable, effective automated coating-removal processes that will ensure long and reliable life for jet aircraft engines.

Recent Comments