You have several options when buying spare parts for your advanced robotic automation. There are three good reasons why your systems integrator should also be your OEM parts supplier.

The lack of small items can create big problems. That is especially true when it comes to spare parts. Every process owner and maintenance manager would agree that not having needed repair or consumable parts available can result in big headaches and lost production.

When considering your spare-parts strategy, one of the most important considerations may be the supplier. The right parts provider can do more than simply get you the part you need when you need it. They can actually help you optimize your parts spend and improve your advanced robotics processes.

Process Expertise

Automation integrators, like Shape Process Automation (SPA), can also provide spare parts. One of the most important advantages of relying on your integrator as your parts supplier is that they can play a key role in improving your processes. They have a thorough understanding of your complete application and installed process. That knowledge gives them the foundation to provide you with valuable insights on process improvements.

“When you design, build, commission, and support a customer’s automation project, you fully understand the expectations for, and operation of, that system,” says Bill Heslip, Aftermarket Sales & Service Manager at SPA. “So, when they contact us about parts, we have detailed background on their process. We can use that knowledge to go beyond just getting them the parts they requested. We can figure out why the part failed and guide them on how to avoid failures or extend part life in the future.”

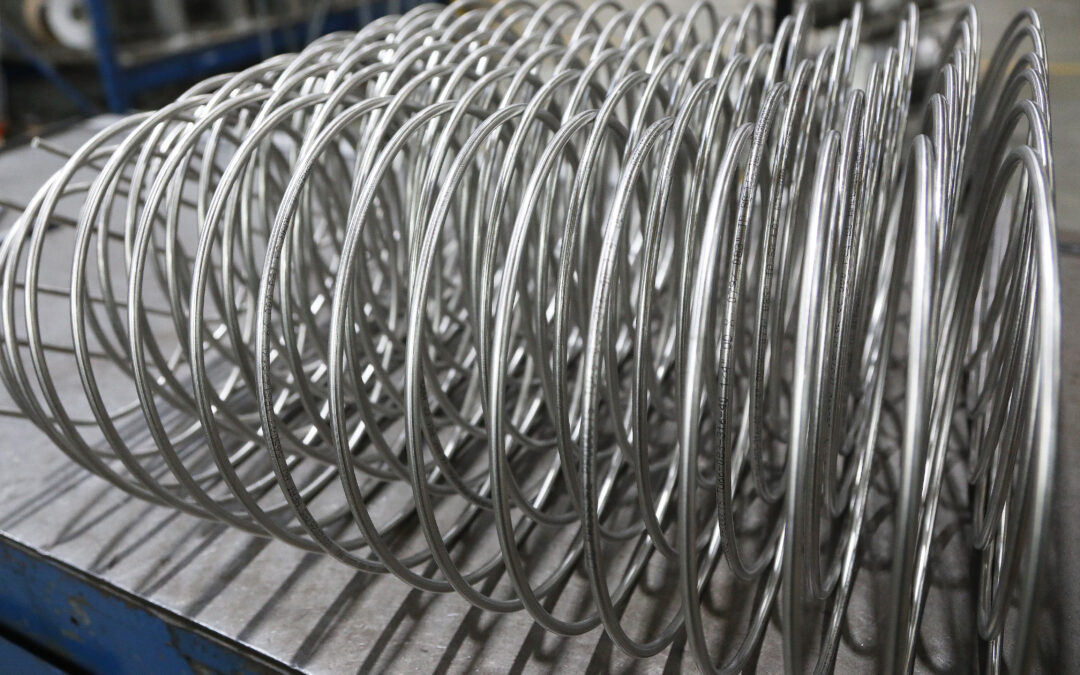

A good example of how integrator expertise provides customer value is waterjet cutting.

“If I see they are buying 700 orifices per quarter across their 30 robots, that’s a red flag, because we typically see numbers closer to 200,” explains Mark Slade, Aftermarket Business Development Manager at SPA. “We’re going to take a look at what’s going on and find ways to reduce their orifice usage.”

“High consumable usage can point to a problem like the quality of the water being used in the process. That means we need to look at their filter type and possibly the replacement frequency. You won’t get that kind of attention or expertise from an OEM or parts distributor.”

Superior Service

Many commonly used spare parts can be easily ordered online from alternative suppliers or a distributor. But aside from not benefitting from the expertise just described, online ordering also means you do not get the speed and personal attention that an organization like SPA can provide.

“Some process owners do a good job of having on hand all the parts and consumables they need,” says Heslip. “But we know that most maintenance is done based on a break/fix approach. That means our customers need their parts right now. We have a customer-focused aftermarket team ready to meet those needs.”

A large percentage of the part orders received by SPA are shipped the same day, with nearly half delivered via next-day air. Local customers can pick up parts at SPA’s Auburn Hills, MI facility or rely on a SPA-dispatched expediter. Customer systems that are still under warranty or have a maintenance agreement can rely on the SPA technicians who are on call around the clock to deliver the part personally.

Lower Costs

You might expect to pay a premium for the higher level of parts-related services described above. But you would be wrong.

“As their integration partner, we know how many robots they have, the type of work they perform, and the environment they operate in,” says Heslip. “We can guide them on the appropriate level of parts to stock on site and adjust our inventory to make sure we’ll have what they need on the shelf.”

Lower costs stem from expertise, which encompasses tailored parts selection, training on proper installation, and advanced-materials-processing knowledge. This ensures customers not only purchase the right parts, but also optimize their operations for efficiency and costs savings.

Choosing the Right OEM Parts Supplier

There is much more to choosing your parts supplier than just considering who has the parts you need. You need to be confident they can get them to you quickly and at the best possible cost.

You have several potential sources for the parts you need for your robotic automation processes. If you’re interested in improving your parts spend, optimizing your processes, and receiving higher level customer service, you should consider relying on your integration partner.

Integrators like Shape Process Automation can serve not only as a reliable parts supplier, but also a valuable partner in your efforts to improve your processes, increase uptime, and reduce your maintenance costs.

24h Service & Support: +1 (248) 829-2795

Spare Parts: +1 (248) 829-2829

Spare Parts Email: parts.na@shapetechnologies.com

Recent Comments