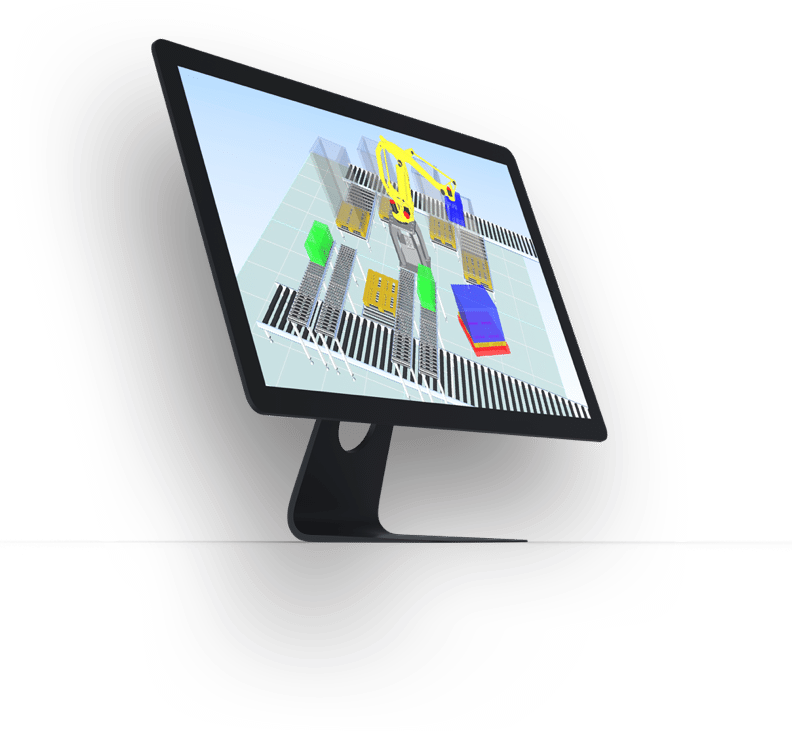

Increase Productivity with Offline Programming

Unleash the full power of your system and maximize ROI with offline programming (OLP). Have a new system being installed? OLP allows you to easily create, program, and simulate your robotic work cell without the physical need and expense of a prototype. Have an existing line? Train your staff or optimize your process without disturbing production.

By using an exact copy of your production software, OLP reduces risk while enabling visualization of single and multi-robot systems prior to install or modification. Transfer a completed program from computer to controller in just one step via USB.

We offer OLP software that is specific to your robot solution, as well as a complimentary suite of software enhancements designed to simplify and optimize training, implementation, and your workflow.

Contact us to learn which OLP software is right for you.

Improve Productivity

Increase Reliability

High Speed, Optimized Path Accuracy & Robot Motion

Reduce Cycle Time

Faster Cut Times

Easy to Train, Program, and Transfer

Process Solutions

We set the bar high for ourselves to continually deliver the highest performing, advanced material cutting solutions available, from anyone and anywhere. That is why every robotic cutting and trimming system we build is optimized for accuracy and efficiency by including a variety of exclusive features that we have developed to ensure your solution maximizes your overall equipment effectiveness (OEE) including:.

- Reduce cycle time without impacting quality

- Faster cut times with optimized path accuracy and robot motion.

- Decrease dross by fine tuning laser frequency and power by material type and robot speed at different parts of the path

- Easily program and preview your cutting path before cutting

- Complete control of your process-specific settings

- Tool Center Point (TCP) autocorrection and enhanced accuracy features

- Manage, store, recall and backup your robot files for specific processes or jobs, including automated fixture or tool change detection

30+ Years of Software Enhancements, Built-In.

Whether you’re cutting automatically with waterjet, laser, or router, our intuitive software enhancements implement specialty algorithms – making software interactions uncomplicated and straightforward, and your parts accurate.

Designed to reduce complexity of automated part programming and to put your operators into production, fast.

-

High Speed Path Accuracy

-

Confine space sharing with multiple robots

-

Macro Embedded Trimming application software

Smarter. Better. Faster.

Improve productivity and increase the accuracy of your parts, quickly and easily without the need to increase your direct labor costs. We proudly offer software solutions that are designed to do exactly that and more.

Multiple Robot Collision Avoidance

Smart detection of robot to robot interference eliminates collisions and drastically improves safety and productivity.

Integrated and 3rd Party Vision Solutions

Faster identification, execution, and lower margins of error, ensuring part accuracy, and improving part quality.

Process-Specific Software Enhancement Suite

Enhances and improves each unique cutting process and application.

JetWare for Waterjet Applications

REAL CUSTOMER EXPERIENCE

Efficiency through Offline Progamming, Proven.

“As far as the cutout shape goes, the Offline Programming was dead on. These programs took one programmer about 8 hours to fine tune and it scrapped 5 parts. To create this program manually, it would take the programmer about 36-40 hours to write and fine tune into tolerance. Also, the manual way would probably scrap about 15-20 parts. In my opinion, the offline programs from Shape Process Automation was almost 100% accurate considering how much time it took to complete the program, how many parts were scrapped, and how far the TCP was from the target.”

– Jason Caroll, Robot Process Engineer at Johnson Controls

Industry Partners

Our systems and solutions combine deep application knowledge, world-class engineering standards, and quality fabrication. You expect the best, and so do we. Accordingly, we’re proud to partner with the following automation industry leaders.