Laser Fast. Laser Focused.

Robotic laser cutting technologies are well-recognized for their ability to quickly produce parts with high accuracy and repeatability. Paired with the advanced automation and application expertise of the team at Shape Process Automation, you’ll witness improvements to your end-to-end manufacturing output.

We’ve developed unique automated laser cutting solutions for 2D and 3D cutting and trimming. We partner with industry-leading suppliers for lasers and robots to solve your manufacturing challenges.

Wondering if laser is the right fit for you? We’re here to help.

Highly Reliable

Solutions for Metals, Plastics, Fabrics, and Composites

Highly Precise Cutting

Fast and Efficient

Safe Operator Set Up

Custom, Turn-key Solutions.

We understand the unique complexities in the manufacturing world and the need to deliver precise parts, faster. Our team of experts will deliver the ideal laser cutting solution to integrate into your operations.

- Ultra-high strength steel structures

- High pressure die cast aluminum structures

- Hydroform tube structures

- Pitching and trimming of interior automotive panels

- External automotive fascias

- Fabric trimming

- And more.…

How Laser Cutting Works: The Power of Light, Put to Work

Lasers use the power of light to transmit and focus energy onto a part that needs to be cut. By super-heating a very small spot very quickly, the material either melts or evaporates. Using a robot to move the laser cutting head, a narrow line of material is removed, leaving the finished-shaped part. Laser is a non-contact process, which simplifies fixturing in many cases. Lasers are used when you need high speed, high quality, or flexibility not possible by other means.

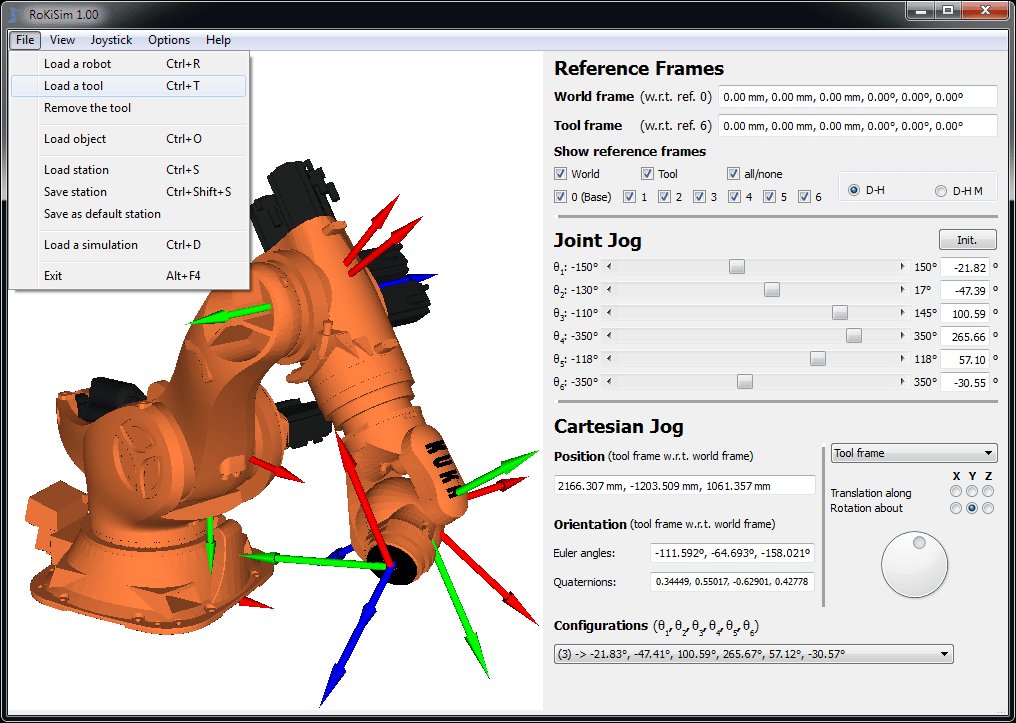

With the right tools, laser cutting with a Shape Process Automation system has never been easier. Tools like HMI-based path adjustments, parametric feature generation, built-in process monitoring equipment, and power-to-speed functions all make owning an Shape Process Autommation system easy to use, easy to recover, easy to maintain.

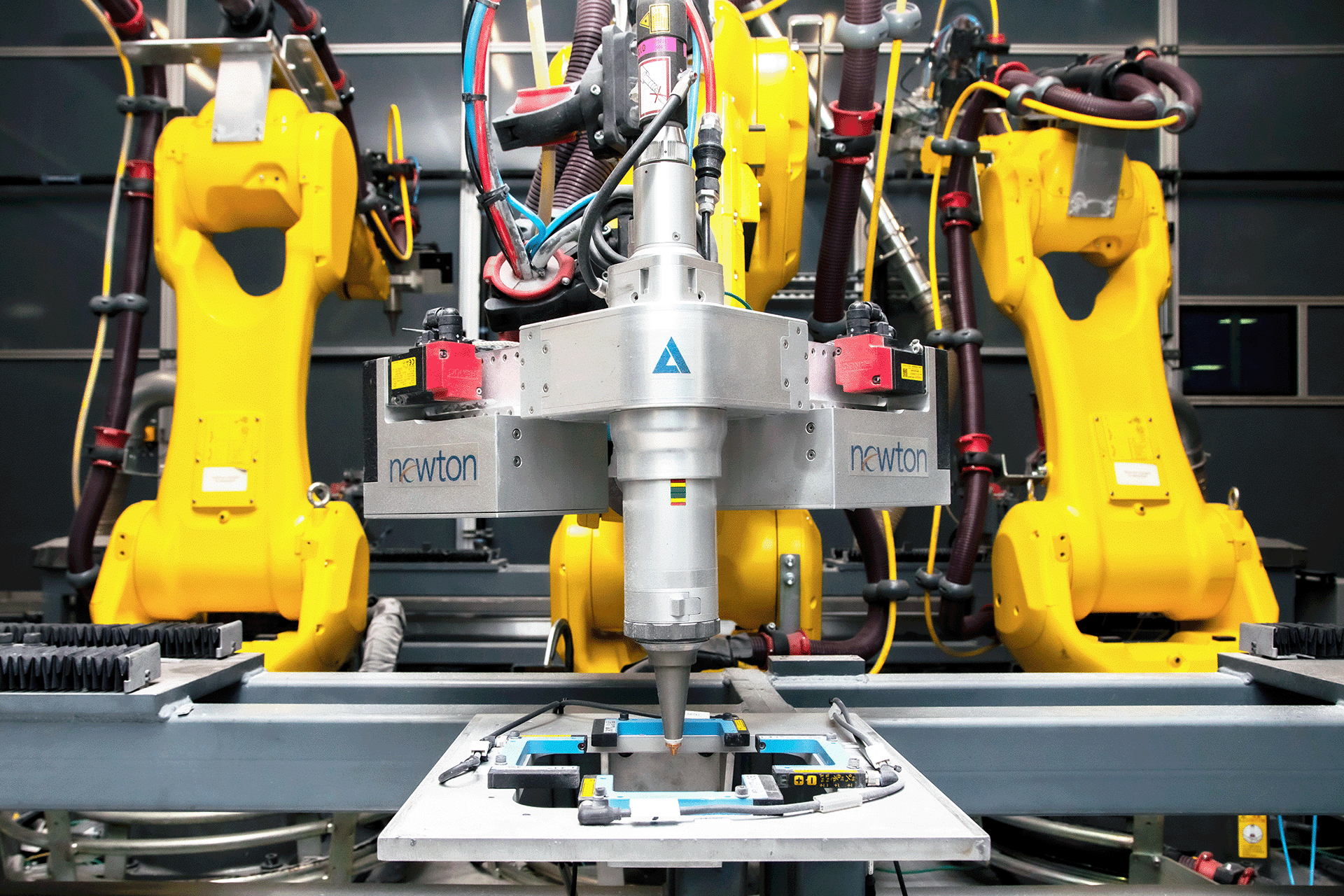

Breakthrough robotic laser trimming technology

NEWTON laser technology enables fiber delivered 6 axis robotics to achieve never seen before cutting speeds and dimensional accuracy on UHSS, hydroform, and aluminum parts. NEWTON technology exponentially reduces capital costs, increases part throughput and dimensional quality compared to traditional robotic laser cutting processes.

Our Laser Cutting Systems

Our solutions are comprised of industry leading laser technology, built on unmodified components from best-in-class suppliers like Trumpf, Laser Mechanisms, Fanuc, and more. Standard components mean you’ll get the most reliability, serviceability, and parts availability from your Shape Process Automation system. Our custom software is optimized for laser cutting, with features that increase OEE, process control, and ease of use.

Options like automatic material handling, dual turntable solutions, built-in part quality inspection, and custom configurations enable efficient integration into production lines at any level of automation.

CO2 Laser Solutions

CO2 lasers are ideal for trimming a wide range of materials like plastics, fabrics, or composites. We integrate with the leading supplier of CO2 laser generators and developed standard user interfaces.

Shape Process Automation has developed a unique beam delivery solution that attaches to an un-modified robot, delivering CO2 laser cutting without restricting the motion of the robot. Where competitors may only use a large, lower-accuracy robot to bring the part to a stationary head, we bring the head to the part using a faster and more accurate robot.

We also deliver cutting solutions incorporating scanners (or galvanometers). These unique cutting heads use servo-controlled mirrors to move the laser beam, making laser cutting at 1000mm/s with very high accuracy possible. Drill dozens of holes per second with ease using this advanced solution.

Fiber Laser Solutions

A popular laser solution, fiber lasers are solid-state solution that delivers the laser beam in a fiber-optic cable. The fiber cable is flexible, allowing for easy integration with robots, and minimal impact to robot range of motion. These specific lasers are most often used to cut metals and black plastics.

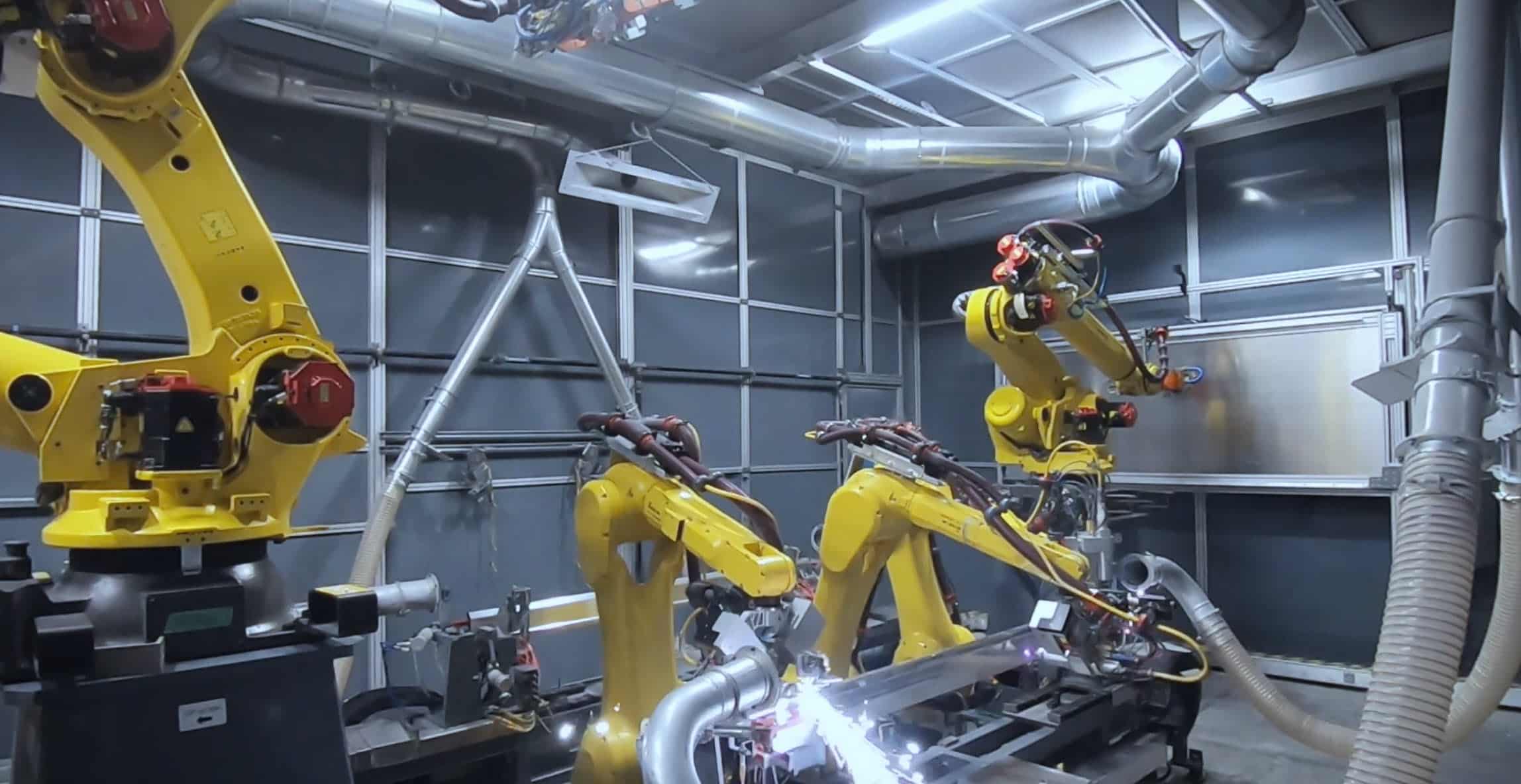

As automotive light-weighting trends drive the use of thinner, harder materials, traditional trimming methods break down. However, fiber lasers have the unique ability to cut today’s press-hardened steel products with ease. When you use multiple robots to operate on the same part, production improves. Cut more parts faster and in a smaller footprint.

Partner With Us for Complete Life-Cycle Support

“As far as the cutout shape goes, the Offline Programming was dead on. These programs took one programmer about 8 hours to fine tune and it scrapped 5 parts. To create this program manually, it would take the programmer about 36-40 hours to write and fine tune into tolerance. Also, the manual way would probably scrap about 15-20 parts. In my opinion, the offline programs from Shape Process Automation was almost 100% accurate considering how much time it took to complete the program, how many parts were scrapped, and how far the TCP was from the target.”

– Jason Caroll, Robot Process Engineer at Johnson Controls

Industry Partners

Our systems and solutions combine deep application knowledge, world-class engineering standards, and quality fabrication. You expect the best, and so do we. Accordingly, we’re proud to partner with the following automation industry leaders.