The Technology of Tomorrow, Today.

We all want a smarter operation – one that connects our technology and production to tracking and reporting for increased optimization. We can connect directly to your MES (Manufacturing Execution System) to track your parts and provide full traceability and production measurements. We bring the technology of tomorrow into your operations, today.

Wondering if a material handling system can improve your bottom line? We’re here to help.

Increase Employee Safety

Improve Quality

Reduce Waste

Optimize Cycle Times

Reduced Downtime and more.

Custom, Turn-key Solutions.

We serve a wide variety of customer needs, some of which can be satisfied within our portfolio of standard robotic cells and turnkey solutions, while others require more custom automation which can be integrated into a current production line.

- Engineered to Order

Custom automation developed around your needs - Configure to Order

Turnkey automation and material processing solutions - Build-To-Print

You supply the prints, we’ll build the solution - Reconfigure Existing Automation

Repurposing your current equipment, or retooling installed solutions

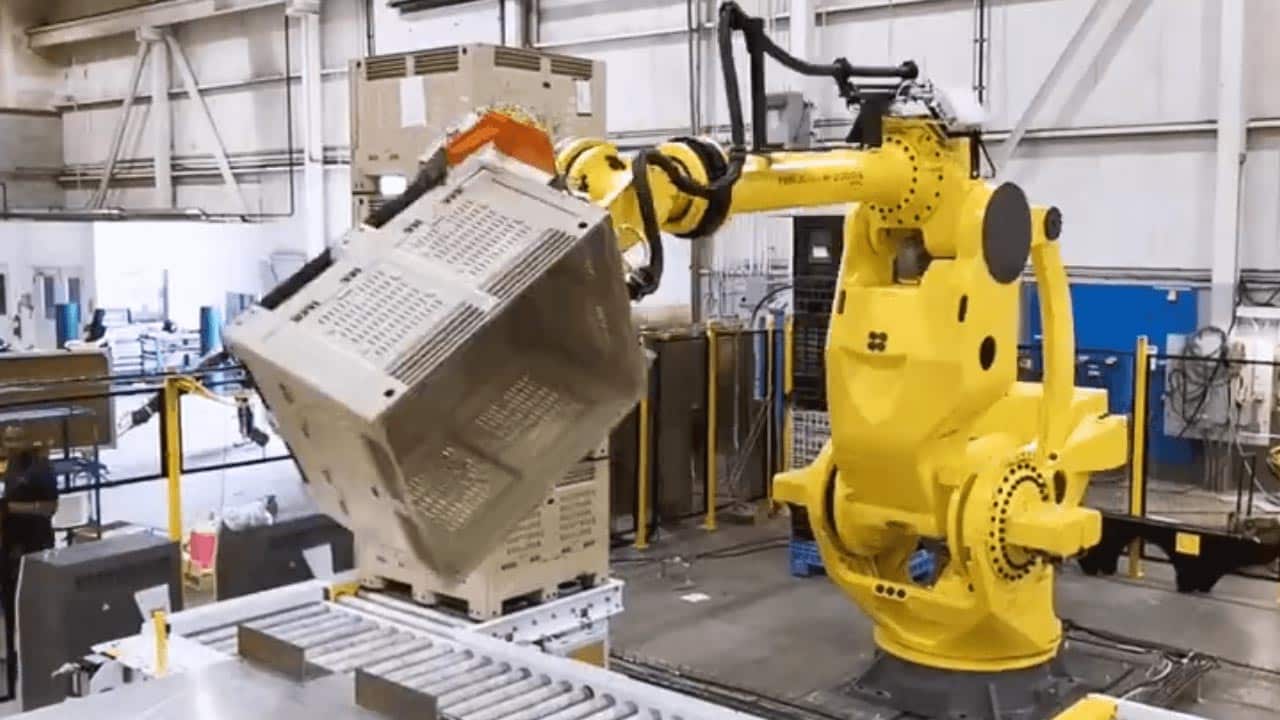

Your Material Handling Experts

Whether you need to move parts, implement a full turnkey pick-pack-pal solution, or something in-between, our Shape Process Automation team will help you automate your material handling and add untapped efficiency to your production.

- Robotic Press Tending

- Assembly and Test Stations

- Inspection and Part Transfer

- Machine Loading & Unloading

- Robotic Cutting & Drilling

- Full turnkey Pick-Pack-Pal Solutions

- Bin-picking

- Tote Dumpers

- And more!

Vision, Optical Metrology, & Artificial Intelligence Solutions

Our team of experts are well-versed in the integration of the latest technology in vision, barcode, RFID, motion control, process, and enterprise software. Working with industry leading technology partners, we help customers track and manage their most important assets – day in and day out.

Reach New Levels of Production

GUIDANCE

Locate parts, off-set robot positions, or implement visual line-tracking

INSPECTION

Measure your parts, pattern matching, poke yoke, go/no-go, presence/absence validation, heat treatment quality control (choral deviation).

IDENTIFICATION

Intelligent reading of barcodes and part specific program selection

OPTICAL CMM INSpection

Stereoscopic measurement so you can make sure your parts are as precise as possible. SPC (statistical process control) for reporting on results.

Artificial Intelligence (AI)

Machine learning implementation right on your production floor so you can continually make improvements.

Industry Partners

Our systems and solutions combine deep application knowledge, world-class engineering standards, and quality fabrication. You expect the best, and so do we. Accordingly, we’re proud to partner with the following automation industry leaders.