Aerospace

Advanced Aerospace Manufacturing

Industry requirements, tolerances, quality, and repeatability demands skyrocket in aerospace manufacturing – and it’s easy to understand why. At Shape Process Automation, we combine in-depth aerospace industry experience with application and process innovation. Our attention to detail and strict QA processes ensure you’re able to reliably meet your customers’ needs.

We have our sights on becoming your preferred advanced process solutions partner, handling the highly engineered products of tomorrow.

Meet SHAPE Partner

For most aerospace applications we partner with Aquarese, an integral part of the Shape Process Automation ecosystem. Aquarese is critical to the successful design and manufacture of our customers next-generation products in Aerospace.

This team of ultrahigh-pressure (UHP) experts delivers waterjet technology for coating removal on aero engines and IGT (industrial gas turbine) for MRO (Maintenance Repair and Overhaul) applications, as well as high pressure waterjet blasting for ceramic shell and core removal on investment, lost wax, or plaster castings.

Aquarese also produces solutions for abrasive waterjet cutting and machining of superalloys and composites including rough and precision cutting, hole drilling & slotting applications, and more.

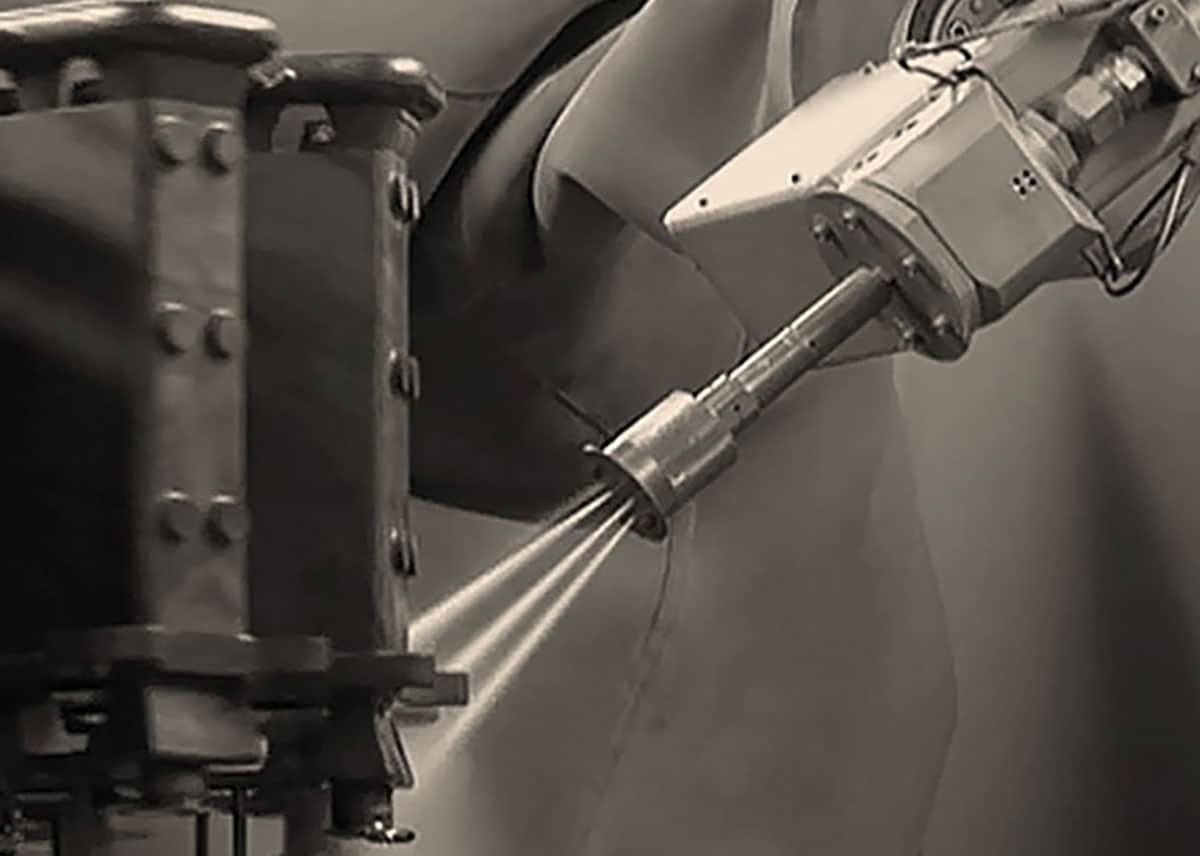

Ultrahigh-Pressure Waterjet Technology

UHP waterjet technology is an extremely versatile process. Cut or trim virtually any material, nearly any geometry, and with precise tolerances. Whether you’re cutting turbine blades, blisks, composites structures, or other complex parts, removing ceramic shell from cast aerospace alloys or removing coatings as part of engine repair activities our ultrahigh-pressure waterjet solutions are a preferred processing method for industry leading organizations.

Waterjet Machining

Content Here

Waterjet Stripping

Content Here

Shell Removal & Degating

Content Here

EXPLORE OUR APPLICATION SOLUTIONS:

Waterjet Blasting for Ceramic Shell & Core Removal

High pressure waterjet blasting is the ideal solution for ceramic shell and core removal on investment, lost wax, or plaster casting for any material.

A fully automated solution, blasting allows for removal of 99% or more of the shell in a single operation without chemical leaching, manual waterblast, and bead blasting.

Automated High-Pressure Waterjet is highly applicable to core removal and yields high productivity with precisely directed rotating waterjet, unaltered inner surface finish and geometry, and is an eco-friendly and operator-safe solution.

Waterjet Coating Removal for Aero Engines Components & IGT

Shape Process Automation’s ultrahigh-pressure waterjet stripping (WJS) solutions remove tough coatings on aero-engine and IGT components with ease. With a shearing force higher than the strength limit of the material, soft and hard deposits like thermal barriers, wear-resistance, or corrosion-protection, and resins, adhesives, rubbers and more, are removed efficiently, safely, and cost-effectively.

Our highly efficient rotary system – Aqualance™ – offers an array of jet options. Aqualance boasts 1500 hours before a major maintenance interval – up to 5x the lifetime of competitor systems.

Full Service & Support

We’re here, whenever you need us. Our team of service and support specialists are located across the globe and dedicated to your success. Our commitment to our customers makes us different and our actions prove it.

Automate Live Interview – Aerospace Industry

Simon Kenworthy, our Senior VP of Global Systems Sales, discussing ultra high pressure waterjet technologies for the Aerospace industry in an Automate Live interview.